PMMA Extrusion sheet

PMMA Extrusion Sheet is produced by using optical grade PMMA material features with high light transmittance and good flatness characteristics. Sheets are extruded inside a class cleanroom environment to ensure high quality and are cover with PE film on both sides and are made by our vendor partner in Taiwan

YEN Nan can offer high quality PMMA Extrusion sheets.

Features

- Use optical grade PMMA material from a leading company in Japan, and insist on using 100% virgin material during the production process.

- The manufacturing facility is equipped with complete production lines from Toshiba Machine that are high precision and fully automated.

- Sheets are extruded inside a class 1K and 10k cleanroom environment to ensure high quality.

- Sheets carry a total light transmittance of 93% with flatness at +/-0.05mm tolerance.

- The vicat softening temperature of 107°C for optical grade light guide plates (LGP) makes it energy saving and easy for processing and secondary forming.

- With good flatness characteristics, the extrusion sheets can form an excellent bond when glued in addition to fewer bubbles in the joint area.

- Sheets have anti-UV agents to block out ultra-violet rays and prevent degradation and yellowing, especially when exposed to the outdoor environment.

Specification

- Thickness: 2 mm - 12 mm

- Width: Max width 1400 mm

- Length: As per customer's requirement.

- Protection: Cover with PE film on both sides

- Standard Size: 1220 mm x 1830 mm & 1220 mm x 2440 mm

Applications

- Windows, Doors, Greenhouses, and Canopies.

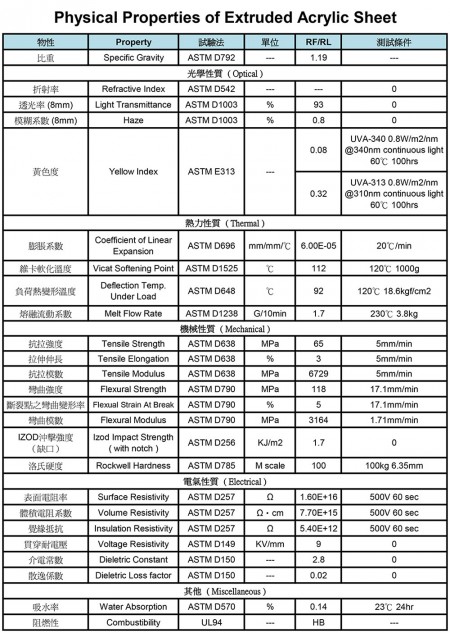

- Physical Properties

- Files

How Can You Maximize Natural Light Transmission While Ensuring Long-Term Durability in Greenhouse Construction?

Our optical grade PMMA extrusion sheets deliver 93% light transmittance to optimize plant growth while anti-UV agents prevent yellowing and degradation over years of outdoor exposure. Manufactured in cleanroom facilities with +/-0.05mm flatness tolerance, these sheets ensure consistent performance and easy installation. Contact us to receive technical specifications and samples tailored to your greenhouse project requirements.

Our PMMA extrusion sheets are engineered for versatility across windows, doors, greenhouses, and canopies, featuring anti-UV agents that prevent degradation and yellowing in outdoor environments. Available in thicknesses from 2mm to 12mm with maximum width of 1400mm and customizable lengths, these acrylic panels exhibit excellent bonding characteristics with minimal bubble formation in joint areas. Backed by our vendor partner's advanced manufacturing capabilities in Taiwan and YEN NAN's 38 years of acrylic expertise, we deliver consistent quality that meets the rigorous demands of architectural design, agricultural facilities, and industrial applications. Contact us today to discuss your specific requirements and experience the superior performance of our optical grade PMMA extrusion sheets.